A sieve manufactured by mounting sieve cloth, electroformed product, or perforated plate in the frame, made for use in particle size Investigation by sieving. Also, see Take a look at Sieve

Similar to some other Device, sieves have to be effectively taken care of to make certain their accuracy and lengthen their lifespan. In addition, verifying the mesh size of a sieve is crucial to ensure exact particle size separation.

The benefits of sieve Examination consist of small financial investment expenditures, straightforward handling, exact and reproducible results in a comparatively limited time and the chance to different the particle size fractions. For that reason, this method is usually used as opposed to techniques working with laser mild or graphic processing.

This cookie is used to recognize the visitor on re-entry. This cookie allows to collect info on person conduct and makes it possible for sharing functionality supplied by Addthis.com

Both may lead to inaccurate outcomes, emphasizing the value of regular sieve checks. It’s advisable to examine examination sieve sizes every single 6 to twelve months, with regards to the degree of use.

Account icon An icon in The form of a person's head and shoulders. It typically implies a user profile. Login Testimonials Chevron icon It indicates an expandable area or menu, or sometimes earlier / upcoming navigation options.

On the subject of accuracy, the screen media you end up picking is important, because it controls what particles go and what particles get retained with a take a look at sieve. This is exactly why it is important which you understand how the more commonly used and readily available take a look at sieve variants compare.

Deciding on the appropriate sieve mesh size is often a significant determination that relies on the particle size distribution of the fabric, business-unique necessities, the intended software, and can reap the benefits of skilled guidance for best benefits.

Sieving is carried out to The purpose where by the sample mass on Each and every click here sieve isn't going to change (= consistent mass). Each and every sieve is weighed, and the quantity of each fraction is calculated in weight p.c, giving a mass-dependent distribution.

Mesh number represents the amount of wires for each inch (25.4 mm). Woven wire sieves are marketed both by mesh selection or because of the wire spacing. The ASTM American benchmarks use mesh quantities, While ISO/BS Worldwide and British standards tend to use wire spacing.

This inverse partnership is vital for sieving processes because it dictates the size of particles which can be segregated from a mix.

HK Technologies can meet up with these here significant standards whilst still presenting flexible remedies into the pharmaceutical industries desires. We provide more compact lab styles in one or various deck sieving, moveable check screeners or larger creation styles.

A mesh sieve, often called a sifter, is actually a tool crafted from a metal great-mesh weave using a handle attached. It can be used to aerate and independent dry substances, leading to a lighter plus much more tender crumb in baked items.

Regular Reference Resources (SRMs) are precision-sized powders or glass beads to check the general performance of sieves and compute productive opening sizes. SRMs will also be used to determine the size of mesh openings Otherwise acknowledged.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Josh Saviano Then & Now!

Josh Saviano Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Michael C. Maronna Then & Now!

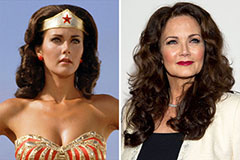

Michael C. Maronna Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!